2025 Reefscape

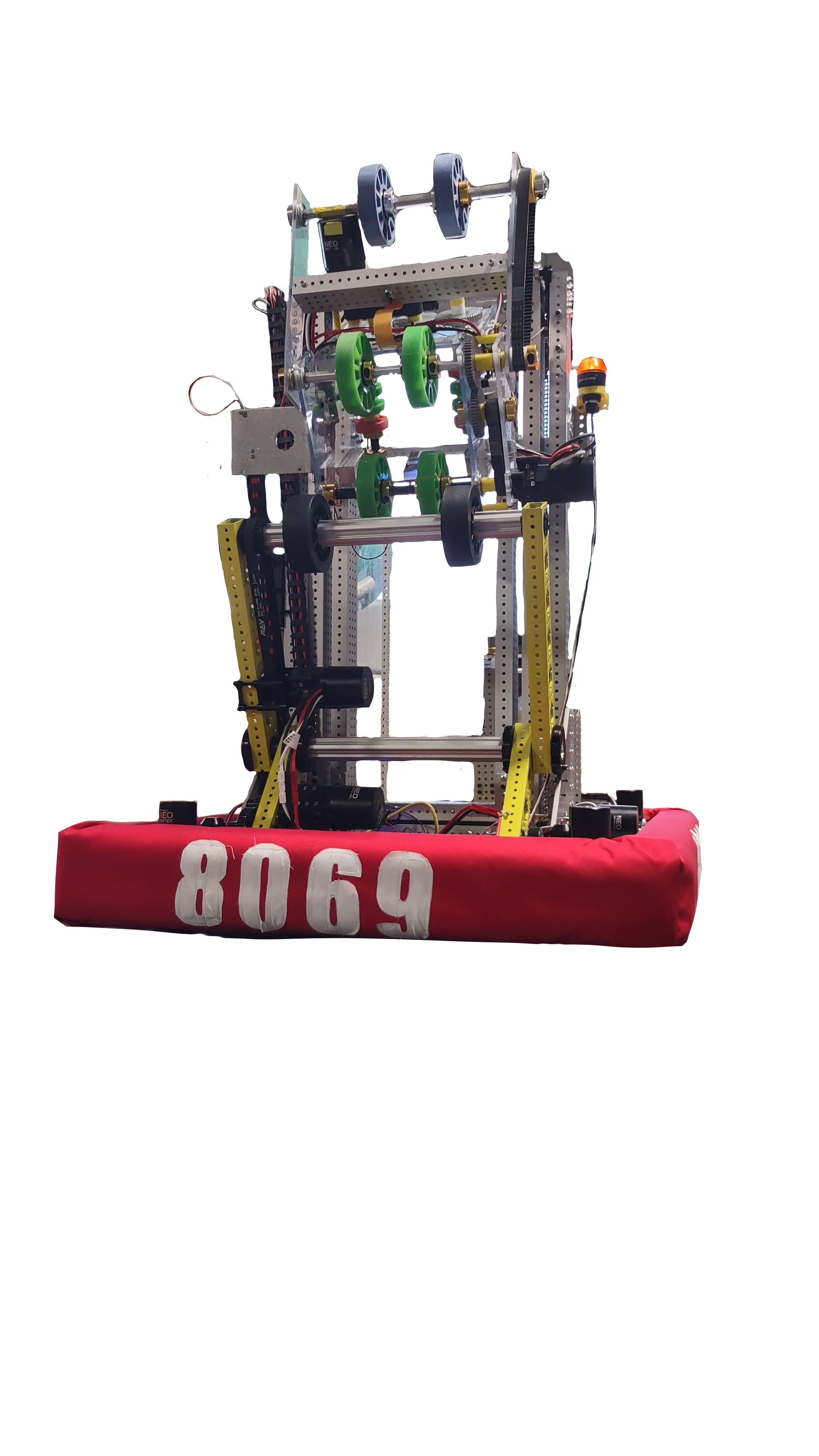

Titan II

In 10 weeks between early January and late March of 2025, the team built a robot, called Titan II (it’s bound to work this time!), to compete in the REEFSCAPE FIRST Robotics Competition. The team had 16 students ages 14 to 18 years old, each working on mechanical and/or software features for the robot. We have been an active robotics team since 2020.

Game Description

For the 2025 game challenge, robots collected PVC coral to place on a reef, cleaned up rubber balls of algae, and hung from cages on the barge.

Frame

Last year's frame was made of 1in x 2in - 1/16in wall MAXTube, and we ended up smashing into a robot and destroying the tubing so we had to patch it. This year we used 1/8 tubing so it would not break. The frame was surrounded by a bumper which is a piece of wood with pool noodles and fabric. We could do it like this because the robots were not as fast. The frame also had a piece of mesh called a belly pan that covered the bottom for mounting electronics and so wires wouldn’t drag on the ground.

Bumpers (A crash course)

We decided to stick with the same bumper design as last year. We used ¾ inch thick wood planks for the frame, placing aluminum L-brackets for support on the outside and inside corners of the frame. For the outer part of the bumper, we used pool noodles for cushioning and attached them with some good old duck tape. At the beginning of the design process, a big problem we ran into was measurements, and a good lesson to take away from the experience was to measure twice and build once, not the other way around. Even after we came to the competition, we still ended up making one more adjustment to the bumpers before we went onto the field. In the end, the bumpers proved to be tough and efficient.

Drivetrain

.png)

Last year was our first time using swerve drive and we used REV Robotics MAX Swerve drive. This year we switched it from NEO to a NEO Vortex which increases drive power. The encoder is built into the motor so it requires less wiring. There are 3 encoders on each swerve drive module . The swerve drive is attached to the frame with six bolts so that way they can't move.

Algae intake

We copied the design of the Algae intake from the REV Starter Bot. This allowed us to have more time to focus on other subsystems. We also painted it yellow and took away two of the wheels to reduce weight. You can find a video of the REV Starter Bot here:

Elevator (The ups and downs)

We started The design process with researching and brainstorming different versions of an elevator. We looked at multiple designs from several different sources like Thrifty Bot, AndyMark,and REV Robotics. Eventually we decided on a variation of the Thrifty Bot elevator.

We initially started with ropes on both the second and first stage but the end result acted more like a spring than an elevator. We switched to chains on the first stage to make it much more rigid and reliable. The method used on the second stage went through a couple variations before we settled on our current design. This design we used proved to be effective and consistent. Our elevator was different from Thrifty Bot’s elevator, in that our design extends a foot taller than the Thrifty Bot elevator.

We were still improving on the elevator at the competition. One of the things we improved on was our second stage. The reason we needed to fix it was because it was bending the brace that supports the second stage; only a minor issue ;). The elevator has three stages which allows it to rise to four preset scoring positions for placing coral on one of the four reef levels. All in all, the elevator is supreme!

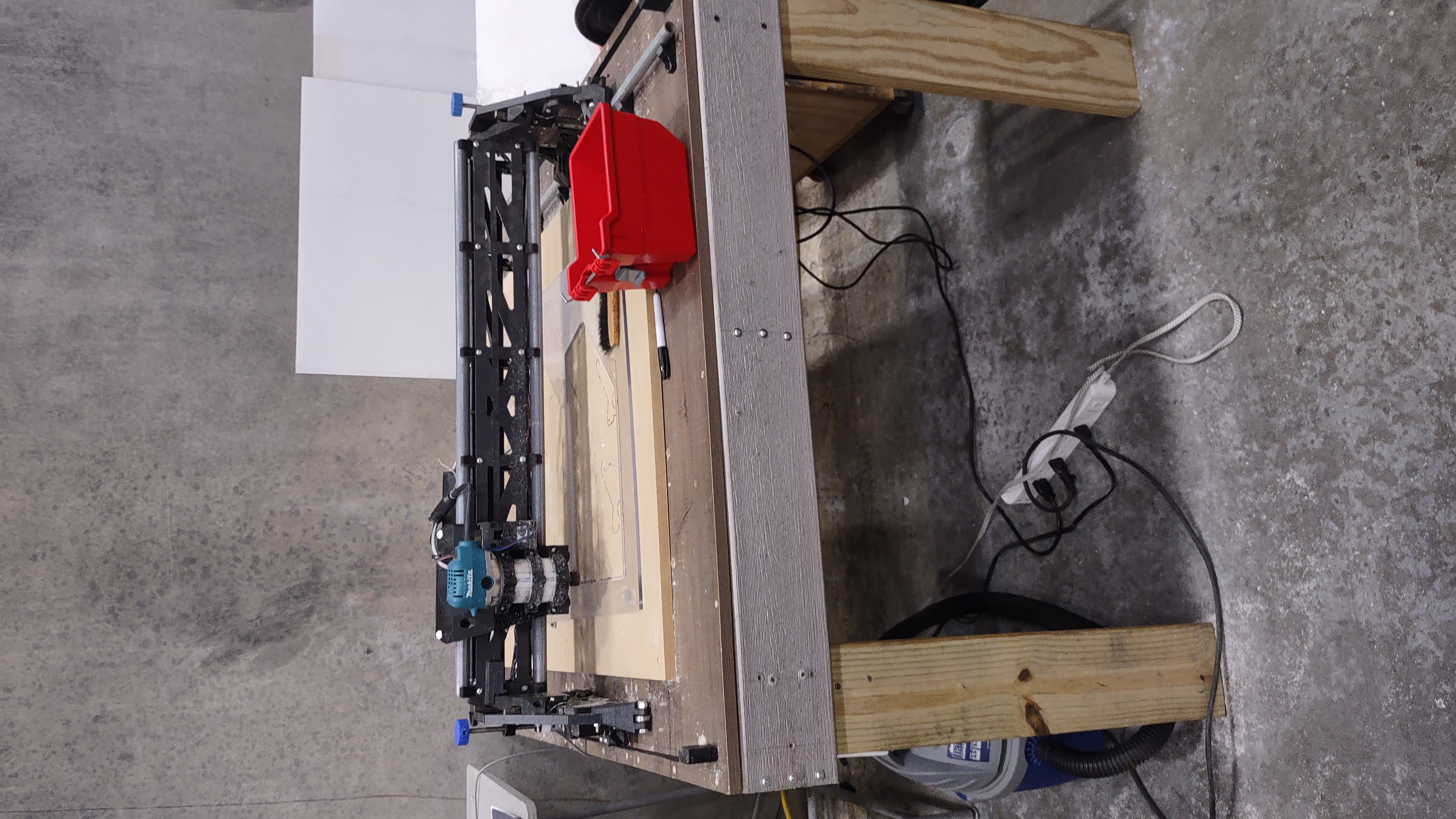

CNC

We found that the CNC works best with lexan/polycarbonate. One of the MANY problems our team had to overcome was the difficulties with our CNC machine. At the beginning of the build season our CNC had many problems such as a dull bit, along with the motor spinning too fast. With this being our first year (summer 2024) using the CNC machine we didn't quite understand the software which was another hurdle that our team encountered. After we got it up and running our bit broke due to the motor going down too fast and moving too fast, so we had to order a new one which took a long time to arrive. With all of the complications, this left us with little time to manufacture our parts that were needed such as our coral chute, coral shooter, and the dealgifier.

Coral chute

The coral chute was made out of four Lexan parts which were cut with our CNC machine.The chute was split into two sides, each connected to a spring-loaded hinge. We used a linear actuator to hold both sides down until the end of the match, then we retract it so that the springs would release and allow the chute to flip up and out of the way. This allowed the chain attached to the cage to be inside our robot when we climbed.

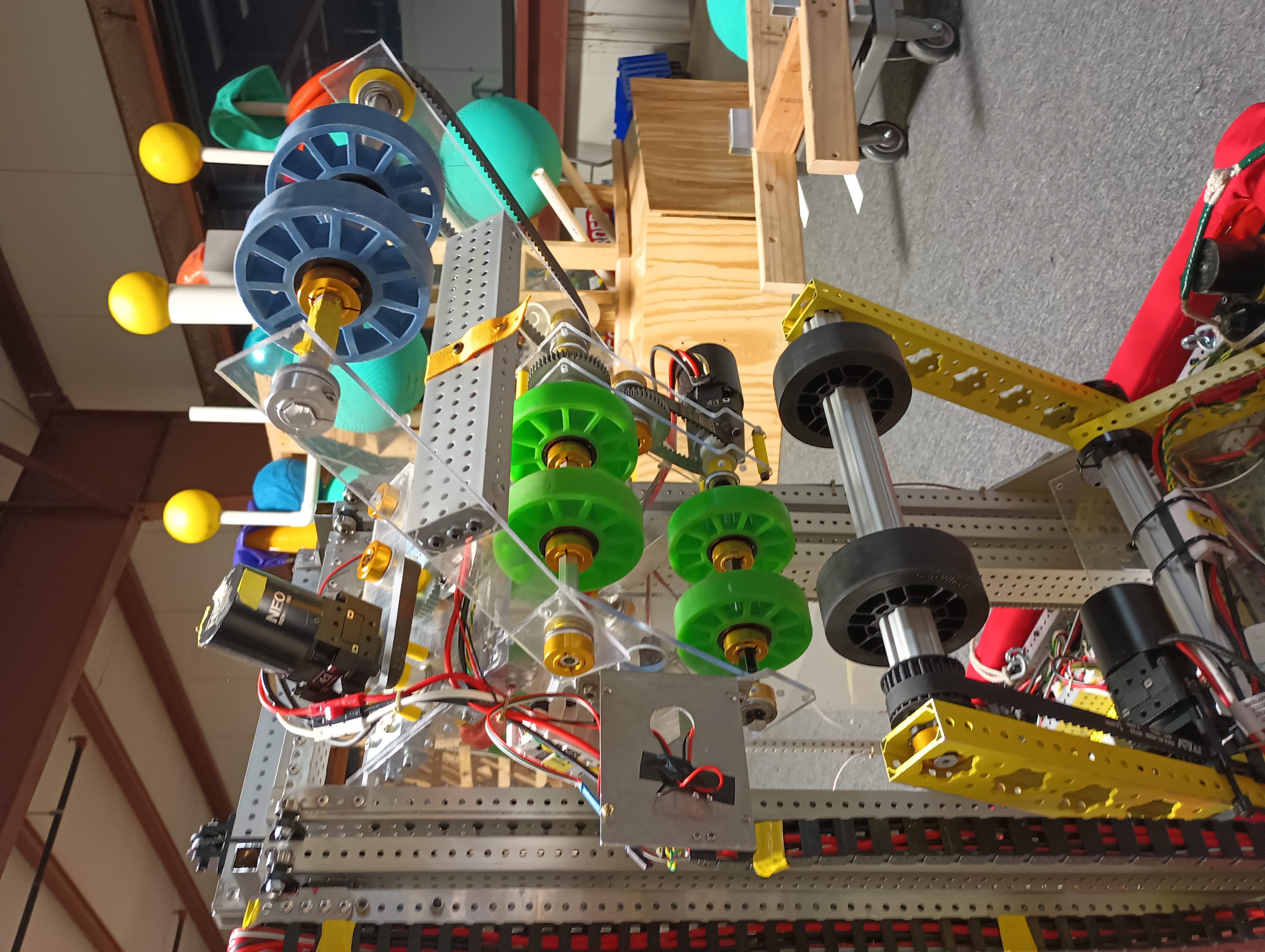

Coral Shooter

The Coral shooter subsystem consists of two pairs of 4” compliant wheels above and below where the coral feeds through the shooter and is powered by a NEO motor. The Coral shooter subsystem also has two sets of 2” compliant wheels, powered by a separate NEO motor, to feed the Coral into the shooter wheels. Also, in order to reduce the weight that the elevator needed to lift, the sides of the shooter were built using CNC’d Lexan. The dimensions of the design were taken from the Cranberry Alarm shooter, but we made several alterations to their design. For example, we decided to make the shooter wheels vertical rather than horizontal in order to connect the dealgifier directly to them. Like in the Cranberry Alarm videos, both of the wheels on the coral shooter must have the same spin power so that the coral comes out at the right angle. We also opted to set it at a fixed angle as it still allows us to score on each level while reducing the complexity.

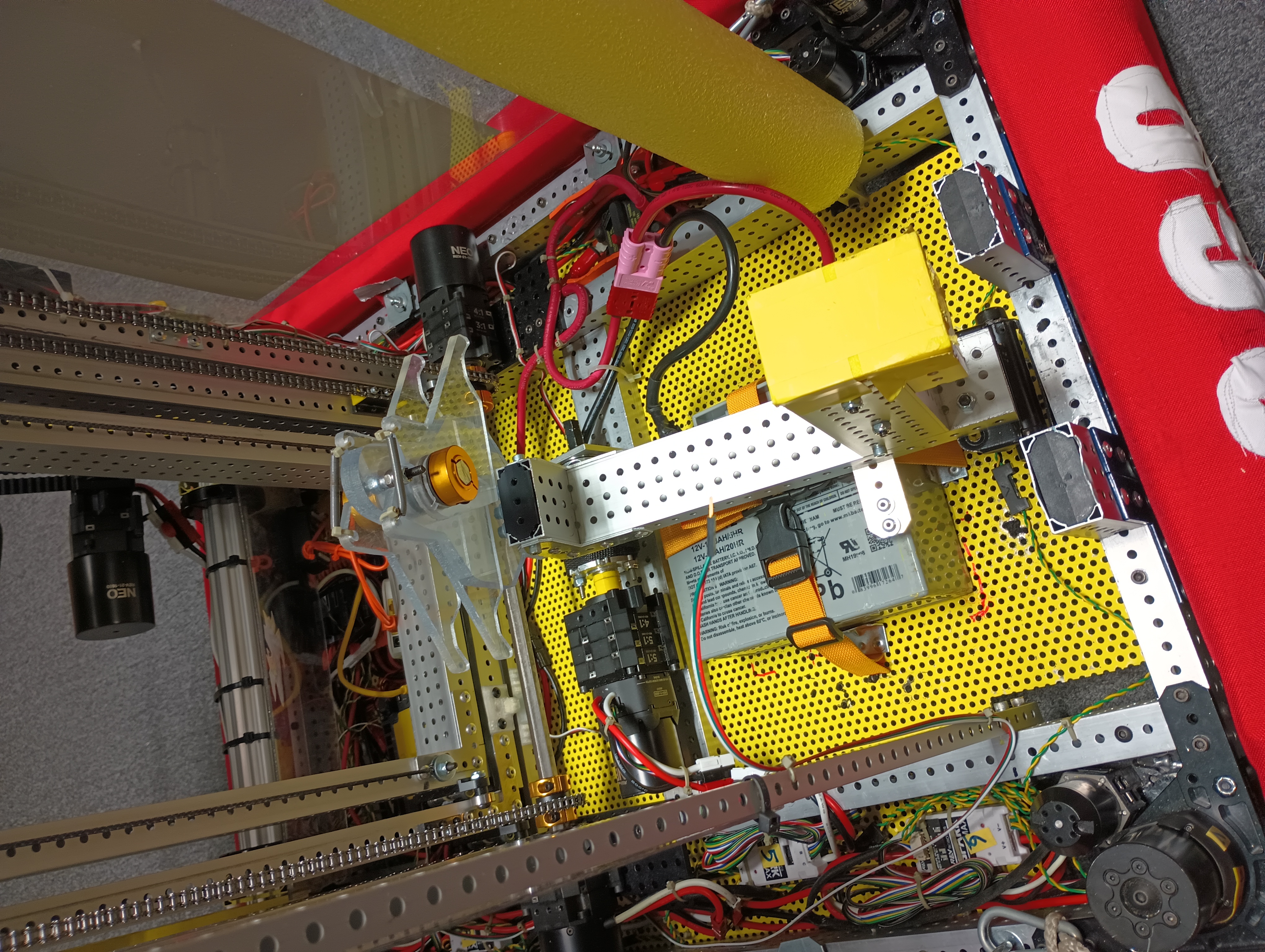

Climb and battery

The mechanism that probably went through the most iterations was the climber. Designed to hang from a deep cage, the climber had to utilize the robot’s center of gravity to slightly suspend the robot from two of the bars of the cage. Originally, we started prototyping a design where one of the bars of the cage was bound between two rollers and pulled horizontally into the side of the robot. This design was too difficult to align with the center of gravity and therefore was scrapped. A similar idea was also tested where the bar was locked into place using a bolt mechanism but this also had durability issues. Finally, after reviewing the 2025 Robonauts’ Everybot design we formulated a climber with a spring loaded grappling hook like design. Combined with a spring loaded gate hinge and a winch, the final climber consisted of a C-shaped arm with the hook reaching 2 inches past the bumper when fully extended. The main obstacle after finishing the climber was making sure it didn’t pull the cage chain into the elevator while still maintaining an acceptable height off the ground. To accomplish this, small pieces of aluminum extrusion were added on either side of the arm to make the cage bind at a higher point, keeping the chain clear of the elevator. Some of these modifications were made during the competition and we successfully climbed during the qualifications and consistently during playoffs.

The battery is a crucial part of any robot. Finding room for it, however, was quite a challenge. We decided that the best place for it was under the climber. An important part of mounting the battery, as we learned in the past, is accessibility. We needed a design that would not hinder the release and replacement of the battery. We found that in the form of straps with a buckle instead of a ratchet. We cut the straps to length,then, using right angle brackets, we pop-riveted the straps between the angle bracket and the stainless steel belly-pan.

Wiring/electronics

Sensors

We use two magnet sensors on the elevator so that it does not go too high or too low. The other sensors we use are light sensors so that when a coral is hitting the front sensor but not the back one it stops so it does not go too far or get stuck.

Wiring

For this year's robot there was lots of wiring to do and many challenges presented themselves. On the elevator we used an energy chain to keep the wires organised and to make sure they didn’t go all over the place. During testing we noticed the SPARK MAX Breakout Board can be installed off by one pin. On top of that there were very few wires we could reuse from last year(which was expected). So there was a lot of wirestripping and crimping to be done.

Code

This year, we used command based java programming. For command based, we define commands, which are specific things that the subsystems do. We can also define sequences of commands. Then each button on the controller can be mapped to one or more commands. This makes it easier to break up the work between the different programmers. It also makes it easier to make sure that we were not trying to do two things at once with one subsystem. Also REV robotics completely changed their code libraries so we had to start from scratch on our drive code.

Auto

This year we used PathPlanner, which let us map out paths we wanted the robot to follow. These paths then use the sensors built into the swerve drive to track its position allowing us to get a precise path. Sadly, there was not enough time to make a fully working auto so we mostly had the robot drive forward.

Competition and awards

In the 2025 St. Louis Regional competition, the Super Hornets competed alongside 44 other teams from across the nation. We reached rank 20th after qualifications on Friday and Saturday morning, and were picked to be in the 7th alliance before lunch on Saturday. The team spoke to the judges during an interview and discussed the team’s attributes, robot functions, and sponsors. We did quite well, efficiently explaining our unique design choice of an unhinging chute <- (Make text link back to chute section), which the judges later described as “Highly reliable and remarkably simple, standing out for its elegance and functionality,” and earned ourselves the Creativity Award (Sponsored by Rockwell Automation). Watch the awards ceremony here:

Strategy

This year’s game contained surprisingly deep levels of strategy. During the design strategy teams had to decide between focussing on coral or algae, as well as deciding which scoring locations to focus on. In early analysis of the game, many teams realized that teams cannot score ranking points, points separate from match points used in determining a teams seed in alliance selection, and because of this teams often decided to value algae less. However, teams later realized that because there are limited scoring locations for coral, at higher levels of play the reef may become entirely filled, causing algae to become the only remaining method of scoring. The limited number of algae present on the field also forces teams to choose between prioritizing scoring algae first, before the other alliance can but risking being unable to score enough coral to make it worthwhile, or score coral force and risk the other alliance scoring all the algae.